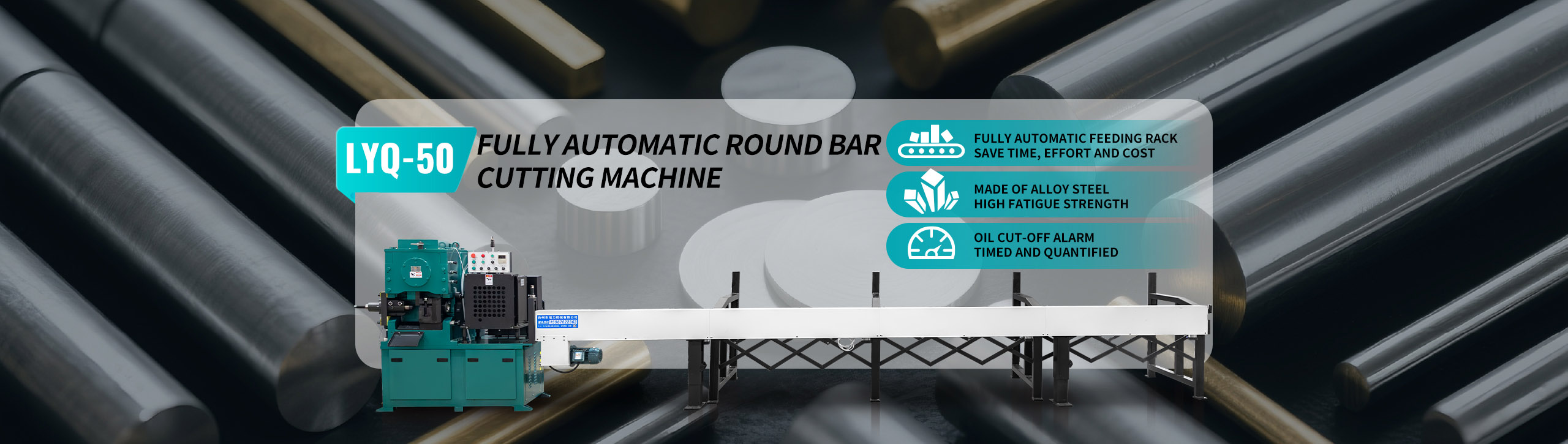

Features:

Equipped with a fully automatic feeding rack and an automatic centering device, it eliminates the need for manual loading, turning and feeding. One operator can manage multiple machines, reducing labor intensity and saving costs.

Adopting a fully enclosed flip-type knife mold, which allows for convenient tool change. It can rotate 360 degrees and be reused, ensuring a longer service life.

Made of reinforced gear alloy steel with standardized heat treatment, providing large transmission torque.

The crankshaft is made of alloy steel, featuring high rigidity and strong fatigue resistance.

Professional bimetallic sliding guide rails offer excellent wear resistance and durability.

The guide rail lubrication is added by an automatic oil pump, with automatic alarm for oil cut-off.

The reasonably designed material stopping mechanism ensures accurate blanking size and convenient adjustment.

A closed gearbox is adopted, where gears and bearings are immersed in oil for reliable lubrication.

The optimized material stopping design results in more precise blanking size, smaller weight deviation and higher flatness of the section.

The equipment is equipped with an automatic centering device, so there is no need to adjust the height of the feeding rack when cutting round steel of different diameters.

.png)

Southeast Industrial Zone, Songmen Town, Wenling City, Zhejiang Province

+86-15967022363

+8615967022363

tzbeili@163.com