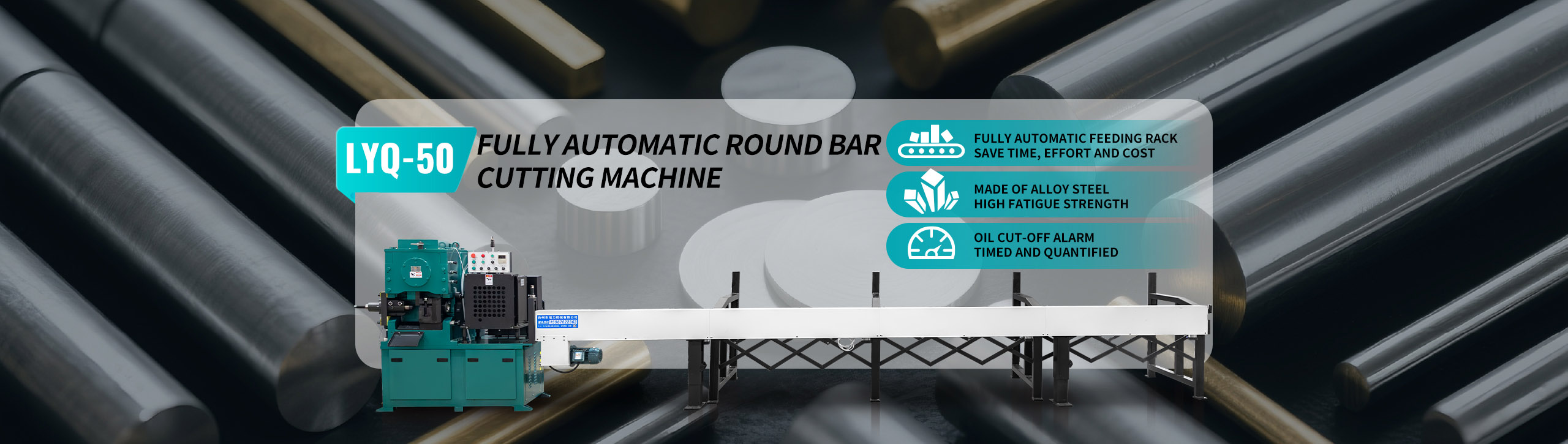

High Efficiency

Adopting advanced Japanese sawing and feeding structure design, it achieves faster feeding and larger torque sawing, ensuring higher cutting efficiency and better stability.

Equipped with a fully automatic loading and feeding structure, it realizes unmanned operation, effectively reducing loading time, saving labor and improving efficiency.

Matched with precision circular saw blades, it achieves highly consistent matching during sawing, gives full play to sawing efficiency and significantly increases unit output.

High Precision

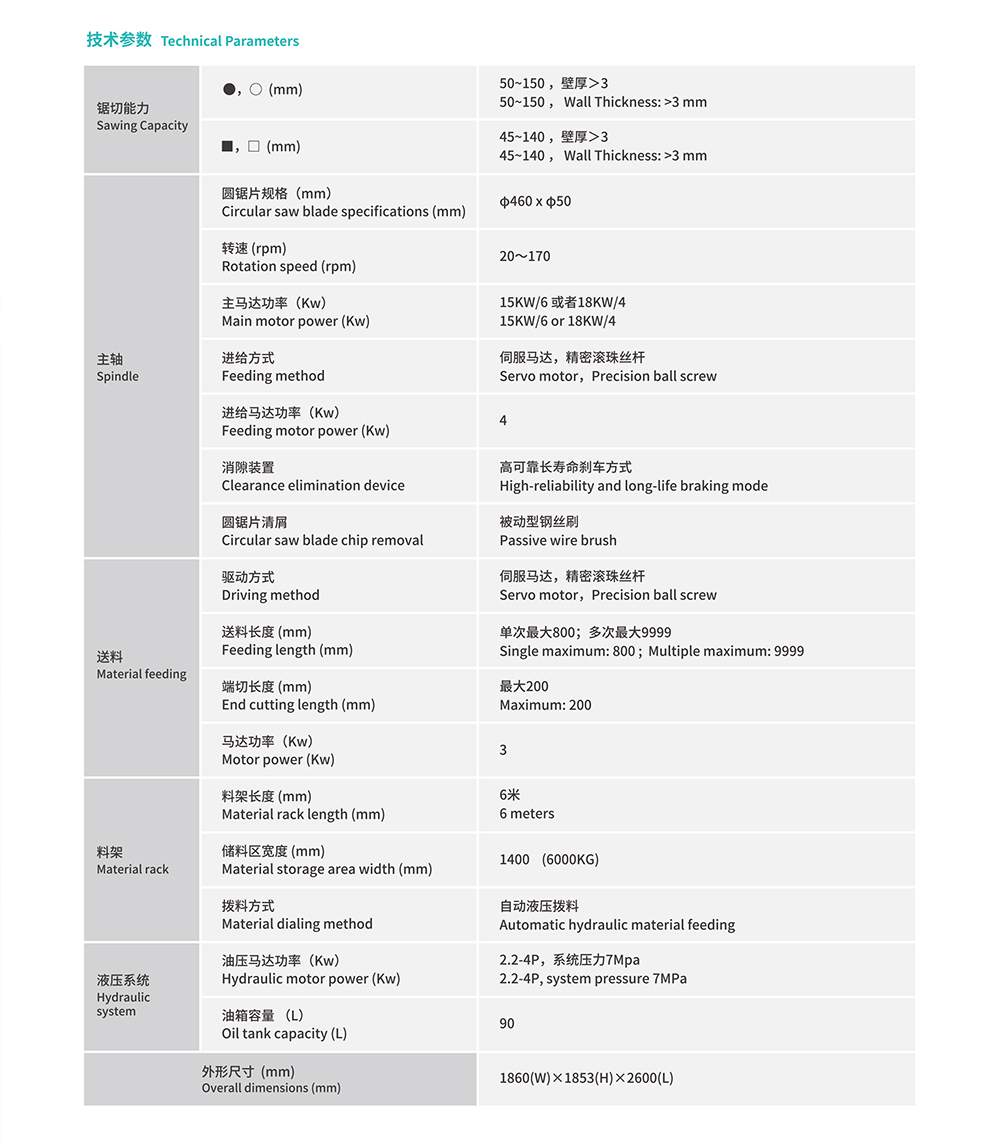

Key components such as lead screws, guide rails and servo motors are all of original imported brands, ensuring higher transmission precision and sawing precision.

Equipped with an automatic control backlash controller, it achieves higher sawing precision and longer service life of circular saw blades for sawing workpieces of different materials.

The electrical and control systems adopt international brands, and the control program software is independently developed, making the operation more convenient and the sawing more precise.

High Stability

The bed adopts finite element analysis, so that the force is more uniform during sawing, making each process run more stably and the equipment precision retention longer.

All components of the equipment are of world-renowned brands, minimizing the failure rate and making the equipment operation safer and more stable.

The sawing feed system adopts a unique guide rail and lead screw transmission structure, which makes the bearing capacity larger and the vibration smaller during sawing, and the product processing more stable.

.png)

Southeast Industrial Zone, Songmen Town, Wenling City, Zhejiang Province

+86-15967022363

+8615967022363

tzbeili@163.com